Safety Information

Always follow safety guidelines to avoid injuries or equipment damage. Read the manual thoroughly before starting installation. Ensure proper grounding and ventilation. Wear protective gear during handling. Refer to the manual for specific safety symbols and labels indicating potential hazards. Follow all manufacturer instructions to ensure safe installation and operation.

- Ensure the unit is installed by a qualified technician.

- Avoid electrical hazards by disconnecting power before servicing.

- Use genuine parts to maintain safety and efficiency.

Adhere to all local safety regulations and standards during installation.

1.1. Safety Precautions

Always follow safety precautions to prevent accidents and ensure proper installation. Handle the unit with care to avoid damage. Keep the system upright during installation to prevent refrigerant leaks. Wear protective gear, including gloves and safety glasses. Ensure the area is well-ventilated and free from flammable materials. Never attempt installation without proper training or tools. Follow all manufacturer guidelines and local safety regulations.

- Avoid over-tightening connections to prevent system damage.

- Use genuine Goodman parts for compatibility and safety.

- Ensure proper grounding to prevent electrical hazards.

Refer to the manual for specific safety symbols and labels indicating potential risks.

1.2. Understanding Warning Labels

Warning labels on the Goodman GSX16 are crucial for safe installation and operation. These labels indicate potential hazards, such as electrical risks or refrigerant leaks. Familiarize yourself with symbols like “Danger,” “Warning,” and “Caution.” Each label provides specific instructions to prevent accidents. Ignoring these warnings can lead to serious injury or equipment damage.

- Read labels carefully before performing any task.

- Understand the meaning of each symbol and its implications.

- Follow instructions provided with each warning to ensure safety.

Refer to the manual for detailed explanations of all warning labels.

Installation Requirements

Ensure proper site preparation and gather necessary tools and materials. Installation must be performed by a qualified technician. The unit requires R-410A refrigerant and 208/230V single-phase power. Place the outdoor unit on a level surface, ensuring compliance with local codes and regulations.

- Qualified technician installation is mandatory.

- Use R-410A refrigerant for optimal performance.

- Ensure 208/230V single-phase power supply.

- Install on a level, stable surface.

- Comply with all local building codes.

2.1. Site Preparation

Ensure the installation site is level, stable, and clear of debris. Proper drainage must be provided to prevent water accumulation. For rooftop installations, verify structural integrity and ensure weather-tightness. The area should be accessible and free from obstructions to facilitate smooth installation.

- Clear the area of debris and obstructions.

- Ensure the surface is level and stable.

- Provide adequate drainage to prevent water pooling.

- Verify structural support for rooftop installations.

Compliance with local building codes and regulations is essential. Ensure the area is well-ventilated to prevent gas buildup and maintain safety during installation.

2.2. Necessary Tools and Materials

Ensure you have the required tools and materials for a successful installation. Essential items include tubing cutters, vacuum pump, manifold gauges, and insulation materials. Additionally, a ladder, wrenches, and a drill may be needed. Refer to the manual for a comprehensive list of tools and materials to avoid missing critical components.

- Tubing cutters for precise copper tubing cuts.

- Vacuum pump for evacuating the system.

- Manifold gauges for pressure testing.

- Insulation materials to prevent refrigerant line heat loss.

Having all necessary tools and materials ready ensures a smooth and efficient installation process.

System Components

The Goodman GSX16 system comprises an outdoor unit with a condenser coil and fan, an indoor unit with an evaporator coil, and connecting refrigerant lines.

3.1. Outdoor Unit Components

The outdoor unit of the Goodman GSX16 includes a high-efficiency condenser coil, a direct drive propeller fan, and a two-stage scroll compressor. It features a durable cabinet with a top discharge for condenser air. Service ports are provided for easy access during maintenance. The unit operates on R-410A refrigerant, ensuring environmental compliance and optimal performance. The fan motor is a two-speed PSC type, designed for reliable operation. Proper installation ensures efficient heat exchange and system longevity.

3.2. Indoor Unit Components

The indoor unit of the Goodman GSX16 system includes the evaporator coil, a multi-speed fan, and a control board for system operation. It also features a high-efficiency two-stage scroll compressor for precise temperature control. Integrated ComfortBridge Technology enhances communication between indoor and outdoor units, ensuring optimal performance. The unit includes a condensate drain pan and connections for refrigerant lines. Proper installation ensures efficient airflow and reliable operation.

- Evaporator coil for heat exchange.

- Multi-speed fan for quiet operation.

- Control board for system management.

System Assembly

Assemble the system by connecting the outdoor and indoor units, ensuring all components are securely fastened. Follow the manual for proper alignment and connections.

- Connect refrigerant lines carefully to avoid leaks.

- Ensure electrical connectors are tightly secured.

- Verify system integrity before powering on.

4.1. Installing the Outdoor Unit

Install the outdoor unit on a level surface, ensuring proper drainage and airflow. Secure it firmly to prevent vibration and noise. Ensure the site can support the unit’s weight and maintain weather-tight integrity if installed on a roof. Follow the manual for correct positioning and fastening. Proper installation ensures efficient operation and longevity of the system. Always adhere to local building codes and safety guidelines.

- Place the unit on a sturdy, level base.

- Ensure adequate clearance for airflow.

- Secure the unit to prevent movement;

4.2. Installing the Indoor Unit

Install the indoor unit in a suitable location, ensuring proper drainage and airflow. Position it on a level surface and connect it to the outdoor unit using refrigerant lines. Follow the manual for correct electrical connections and ensure all components are securely fastened. Proper installation ensures efficient performance and prevents potential issues. Always consult a licensed technician for complex connections.

- Ensure the unit is level and securely mounted.

- Connect the refrigerant lines carefully to avoid leaks.

- Verify electrical connections meet local codes.

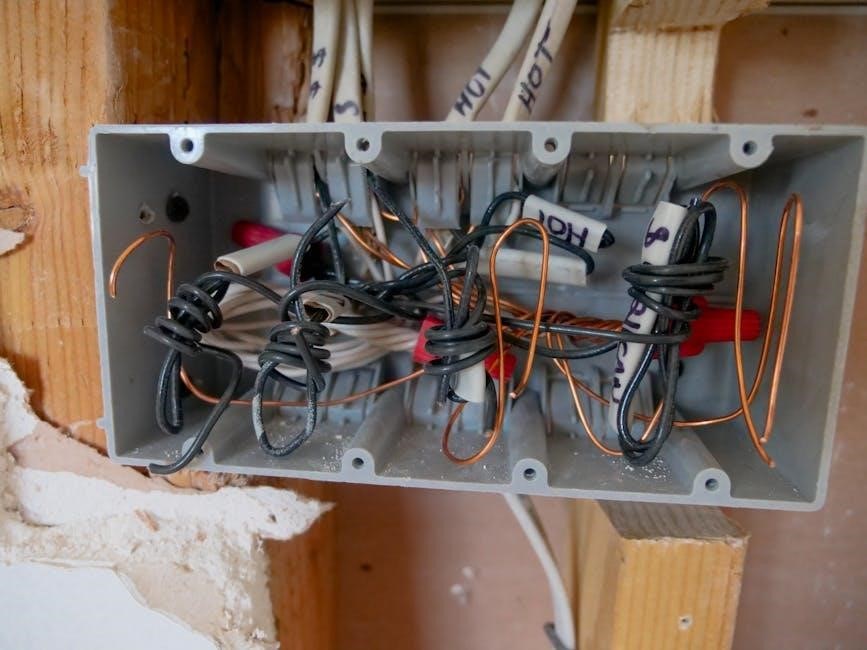

Electrical Connections

Connect the electrical components according to the manual. Ensure compatibility with 208/230V single-phase power. Follow local codes and safety standards for wiring and connections. Verify all circuits are properly grounded before powering up. Refer to the manual for specific wiring diagrams and instructions to ensure safe and efficient installation. Always consult a licensed electrician if unsure.

5.1. Connecting the Outdoor Unit

Connect the outdoor unit’s electrical components carefully. Ensure the wiring matches the unit’s specifications and local codes. Refer to the wiring diagram in the manual for precise connections. Verify the voltage rating (208/230V) and phase requirements before connecting. Use appropriately sized cables to prevent overheating. Secure all connections tightly to avoid loose contacts. Double-check the wiring for proper grounding to ensure safety and efficiency. Consult a licensed technician if uncertain.

- Connect the power supply to the designated terminals.

- Ensure all connections are weatherproof and secure.

- Avoid overloading circuits to prevent electrical hazards.

5.2. Connecting the Indoor Unit

Connect the indoor unit’s wiring and components as outlined in the manual. Ensure the thermostat is properly linked to the unit. Verify all electrical connections are secure and match the system’s specifications. Check the refrigerant lines for leaks and proper insulation. Connect the drainage system to prevent water damage. Turn off power before servicing. Use a vacuum pump to evacuate the system if required. Consult a licensed technician for complex connections.

- Ensure all wires are correctly labeled and connected.

- Verify proper grounding for safe operation.

- Test the system after connecting to ensure functionality.

- Inspect lines for damage before installation.

- Ensure proper alignment of refrigerant ports.

- Refer to the manual for specific connection procedures.

- Use a vacuum pump to evacuate the system.

- Charge with R-410A refrigerant only.

- Verify system pressure matches specifications.

- Verify system operation in all modes.

- Check refrigerant lines for leaks.

- Ensure proper airflow and temperature settings.

- Test system operation in all modes.

- Check for refrigerant leaks using approved methods.

- Verify proper airflow and temperature settings.

- Ensure quiet and stable operation.

- Check temperature differences across coils.

- Verify airflow rates and system efficiency.

- Confirm operation in all modes.

- Ensure compliance with rated performance.

- Inspect filters monthly and replace as needed.

- Clean condenser and evaporator coils annually.

- Check refrigerant levels and electrical connections.

- Inspect and clean drain lines to prevent blockages.

- Verify thermostat settings and operation.

- Ensure proper airflow through vents and grilles.

- Refrigerant leaks: Inspect lines and seal any gaps.

- Low airflow: Clean filters and check vent obstructions.

- Electrical issues: Verify connections and reset circuit breakers.

- 10-Year Compressor Limited Warranty;

- 10-Year Parts Limited Warranty.

- 10-Year Compressor Limited Warranty.

- 10-Year Parts Limited Warranty.

- Registration required within 60 days.

- Height: ~37 inches

- Width: ~54 inches

- Depth: ~43 inches

- Weight: 240–340 pounds

- SEER rating: Up to 16

- Refrigerant: R-410A

- Compressor: Two-stage scroll

- Warranty: 10-Year limited

Refrigerant Line Connections

Ensure proper connections to avoid leaks. Use appropriate materials for insulation. Evacuate the system with a vacuum pump before charging. Follow safety guidelines and manufacturer instructions.

6.1. Connecting Refrigerant Lines

Connect the refrigerant lines carefully to ensure proper system performance. Use a vacuum pump to evacuate the system before charging. Insulate the lines to prevent heat transfer and energy loss. Ensure all connections are leak-free and properly tightened. Follow the manufacturer’s guidelines for line sizing and routing. Always use approved refrigerant handling tools to avoid contamination and safety hazards.

6.2. Charging the System

Charge the system with R-410A refrigerant following the manufacturer’s guidelines. Ensure the system is evacuated using a vacuum pump before charging. Verify the correct refrigerant charge using the system’s specifications. Check for leaks at all connections and ensure proper system pressure. Refer to the manual for detailed charging procedures to optimize performance and efficiency.

Start-Up and Check-Out

Power up the system and verify proper operation. Ensure all components function correctly, including cooling, airflow, and temperature control. Check for leaks and unusual noises. Confirm system performance matches specifications for optimal efficiency and reliability.

7.1. Initial System Start-Up

After installation, power up the system and ensure all components are operational. Check for leaks in refrigerant lines and verify proper airflow. Confirm the system operates in all modes, including cooling and fan-only. Ensure the thermostat is set correctly and the system responds to temperature changes. Verify there are no unusual noises or vibrations during operation. Record initial performance metrics for future reference.

7.2. System Performance Verification

After start-up, verify the system’s cooling and heating performance. Check temperature drop across the evaporator and condenser coils. Ensure airflow is balanced and meets manufacturer specifications. Verify the system achieves the rated SEER and operates efficiently. Test all modes, including cooling, heating, and fan-only, to confirm proper functionality. Record performance metrics for future reference and ensure compliance with installation standards.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance and prevents issues. Check filters, clean coils, and inspect electrical connections. Address common problems promptly to avoid system downtime.

8.1. Regular Maintenance Tasks

Regular maintenance is essential for optimal performance and longevity. Inspect air filters monthly and replace them as needed to ensure proper airflow. Clean condenser and evaporator coils annually to maintain efficiency. Check refrigerant levels and electrical connections for leaks or damage. Lubricate fan motors and inspect belts for wear. Schedule professional inspections annually to address potential issues early.

8.2. Common Issues and Solutions

Common issues with the Goodman GSX16 include refrigerant leaks, improper airflow, and electrical connection problems. Inspect lines for leaks and tighten connections if necessary. Ensure filters and coils are clean for optimal performance. If the system does not cool, check thermostat settings and verify refrigerant levels. Reset the system if it trips or shuts down unexpectedly. Addressing these issues promptly ensures reliable operation and energy efficiency.

Warranty Information

Goodman GSX16 offers a 10-Year Compressor Limited Warranty and 10-Year Parts Limited Warranty. Online registration within 60 days of installation is required for coverage eligibility.

9.1. Warranty Coverage Details

The Goodman GSX16 warranty includes a 10-Year Compressor Limited Warranty and a 10-Year Parts Limited Warranty. Registration within 60 days of installation is required for coverage eligibility. The warranty covers defects in materials and workmanship under normal use and conditions. Proper installation by a qualified technician is essential for warranty validity. For full details, refer to the official Goodman GSX16 installation manual.

9.2. Registration and Claim Process

Register your Goodman GSX16 within 60 days of installation to activate the warranty. Visit Goodman’s official website or contact customer service to complete the registration process. For claims, provide proof of installation and serial number. Claims must be submitted through authorized service providers. Ensure all installations are performed by qualified technicians to maintain warranty eligibility. For detailed instructions, refer to the Goodman GSX16 installation manual.

Visit Goodman’s website for registration and claim guidelines.

Technical Specifications

The Goodman GSX16 is available in 1.5 to 5-ton sizes, using R-410A refrigerant. It operates on 208/230V single-phase power and features a direct drive propeller fan. Designed for high-efficiency performance, it includes a two-stage scroll compressor and two-speed PSC condenser fan motor for optimal cooling and energy savings.

10.1. Unit Dimensions and Weight

The Goodman GSX16 outdoor unit dimensions are approximately 37 inches in height, 54 inches in width, and 43 inches in depth. The weight ranges from 240 to 340 pounds, depending on the model size (1.5 to 5 tons). These dimensions ensure compatibility with standard installation spaces while maintaining structural integrity. Always refer to the specific model’s manual for exact measurements, as slight variations may exist. Proper handling is essential due to the unit’s weight and size.

10.2. Performance Ratings

The Goodman GSX16 offers high-efficiency performance with a SEER rating of up to 16, ensuring energy savings and reliable cooling. It operates on R-410A refrigerant, meeting environmental standards. The unit features a two-stage scroll compressor and a two-speed PSC condenser fan motor for consistent performance. With a 10-Year Compressor and Parts Limited Warranty, it provides long-term reliability. Its high-efficiency design meets Energy Star certification, optimizing energy use and reducing operational costs.

Additional Resources

Visit GoodmanMfg.com for online support, downloadable manuals, and contact information. Access troubleshooting guides, technical specifications, and warranty details for comprehensive assistance with your GSX16 installation.

11.1. Online Support and Manuals

The Goodman GSX16 installation manual is available for download on the official GoodmanMfg.com website. It provides detailed installation instructions, technical specifications, and troubleshooting guides. Additional resources include user guides, repair manuals, and technical bulletins. Visit the literature library section for comprehensive support documents. Ensure to refer to the official sources for accurate and up-to-date information to facilitate smooth installation and maintenance of your GSX16 system.

11.2. Contact Information for Assistance

For assistance, contact Goodman Manufacturing Company at 19001 Kermier Rd., Waller, TX 77484. Visit www.goodmanmfg.com or www.amana-hac.com for support. Refer to the Parts Catalog for specific part numbers and details. Ensure all inquiries are directed through official channels for accurate and reliable assistance with your GSX16 system.